Pneumatic steam control valves are commonly used in industrial applications to regulate the flow and pressure of steam. These valves are operated using compressed air or other gases to control the opening and closing of the valve. Here are some key features of pneumatic steam control valves:

- Pneumatic Actuation: Pneumatic control valves use compressed air or other gases as the actuating medium to operate the valve. The air pressure is controlled to modulate the valve position, allowing precise control over the steam flow.

- Quick Response: Pneumatic valves offer fast response times, allowing for rapid adjustments to changes in steam flow requirements. This ensures efficient control and helps maintain stable operating conditions.

- Proportional Control: Pneumatic steam control valves can provide proportional control, allowing for precise adjustment of steam flow rates. By modulating the valve position based on input signals from a control system, these valves can maintain desired steam pressures and flow rates.

- Fail-Safe Operation: Many pneumatic control valves are designed with fail-safe features to ensure safety in case of power or air supply failure. For example, they may have a spring return mechanism that automatically closes or opens the valve to a predetermined safe position when the actuation pressure is lost.

- Positioners and Controllers: Pneumatic steam control valves can be paired with positioners and controllers to enhance their performance. Positioners receive control signals from a control system and adjust the valve position accordingly, while controllers provide additional functionality such as PID (proportional-integral-derivative) control to optimize the valve’s response.

- High Temperature Resistance: Steam control valves are exposed to high temperatures in steam applications. Pneumatic control valves are typically constructed using materials that can withstand high temperatures to ensure reliable operation and prevent damage.

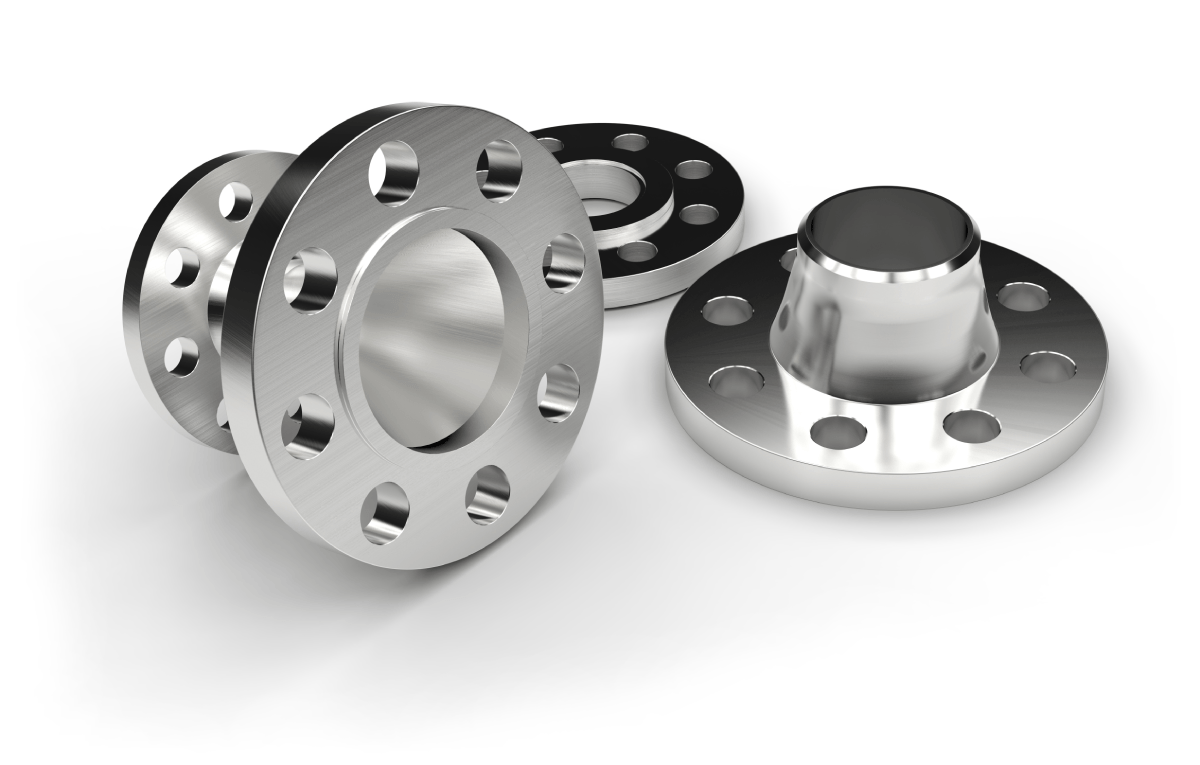

- Corrosion Resistance: Steam can contain corrosive elements, so pneumatic steam control valves are often constructed from materials resistant to corrosion, such as stainless steel or special alloys. This helps extend the lifespan of the valve and maintain its performance over time.

- Modular Design: Pneumatic steam control valves often have a modular design, allowing for easy maintenance and replacement of individual components. This simplifies repairs and reduces downtime in industrial processes.

It’s important to note that specific features may vary depending on the manufacturer, valve type, and application requirements. It is recommended to consult the product documentation or contact the valve manufacturer for detailed information on the features of a particular pneumatic steam control valve.

Use of pressure Gauges

Use of pressure Gauges

Reviews

There are no reviews yet.