Cross Tee

Cross Tee

ERW Steel Pipe

Fire Hydrant

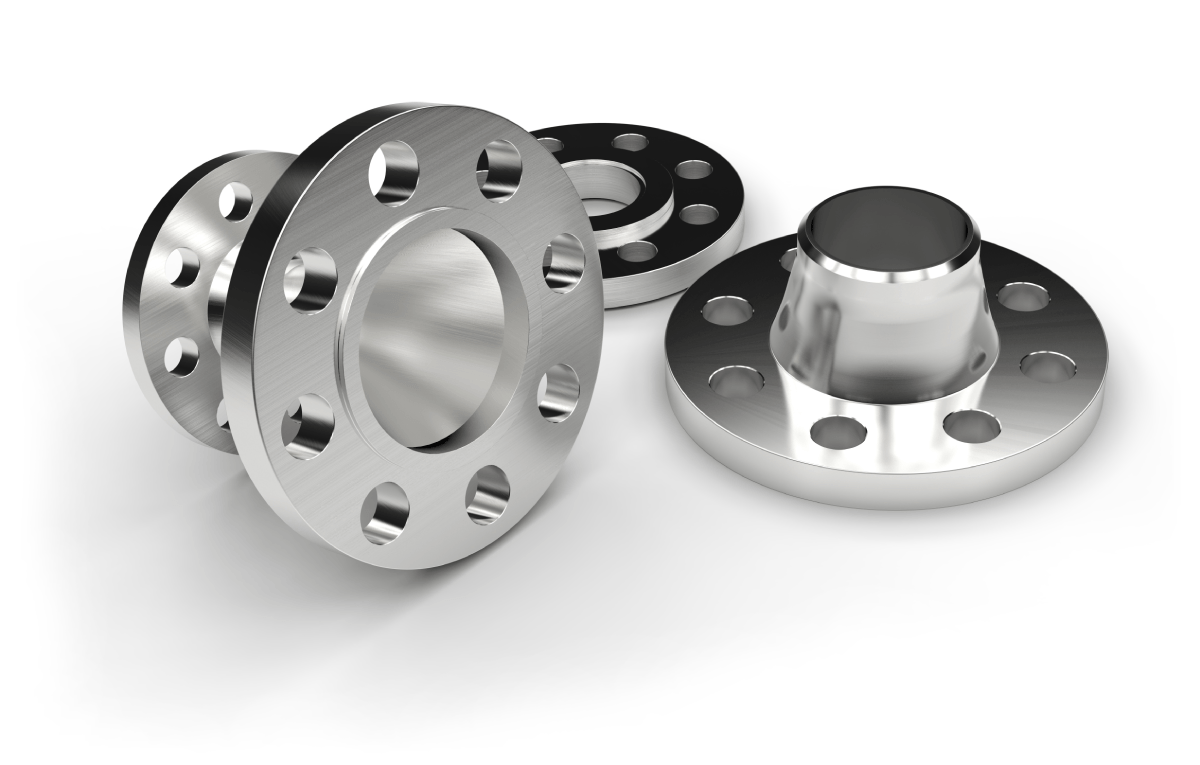

Flanges

Flexible & Ridge Coupling UL listed

- Size Range: UL listed flexible couplings are available in various size ranges to accommodate different pipe diameters. The size range may vary depending on the manufacturer and the specific coupling model. Common size ranges include 1/2" to 12" or even larger.

- Materials: Flexible couplings are typically constructed from durable and corrosion-resistant materials to ensure long-lasting performance. Common materials used include ductile iron, stainless steel, or synthetic rubber compounds.

- Pressure and Temperature Ratings: UL listed flexible couplings are designed to handle specific pressure and temperature ranges. The pressure rating indicates the maximum internal pressure the coupling can withstand, while the temperature rating specifies the allowable temperature range for the coupling's operation.

- End Connections: Flexible couplings have different types of end connections to suit various pipe systems. Common types include flanged ends, grooved ends, or plain ends. The type of end connection should match the pipe system requirements for proper installation.

- Movement and Misalignment Capability: Flexible couplings provide flexibility to accommodate small movements and misalignments between pipe sections. The coupling should be designed to allow for angular, axial, and lateral movement within its specified limits.

- Sealing: UL listed flexible couplings employ sealing mechanisms to prevent leaks at the connection points. This may involve rubber gaskets, O-rings, or other sealing elements that create a watertight or gas-tight seal.

- Installation Method: Flexible couplings can be installed using different methods, such as compression-type couplings, bolted couplings, or quick-connect couplings. The installation method should be suitable for the specific application and compatible with the pipe materials and dimensions.

- Compliance with UL Standards: UL listed flexible couplings have been tested and certified by UL to ensure compliance with specific safety and performance standards. This certification confirms that the coupling meets the required criteria for reliable and safe operation.